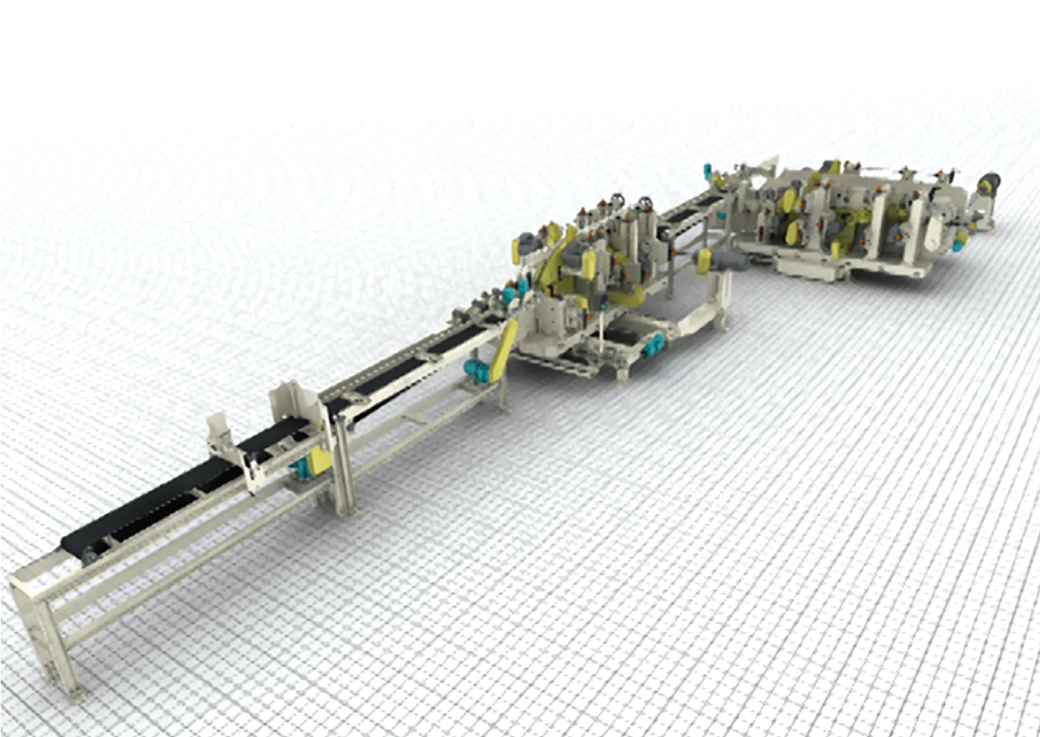

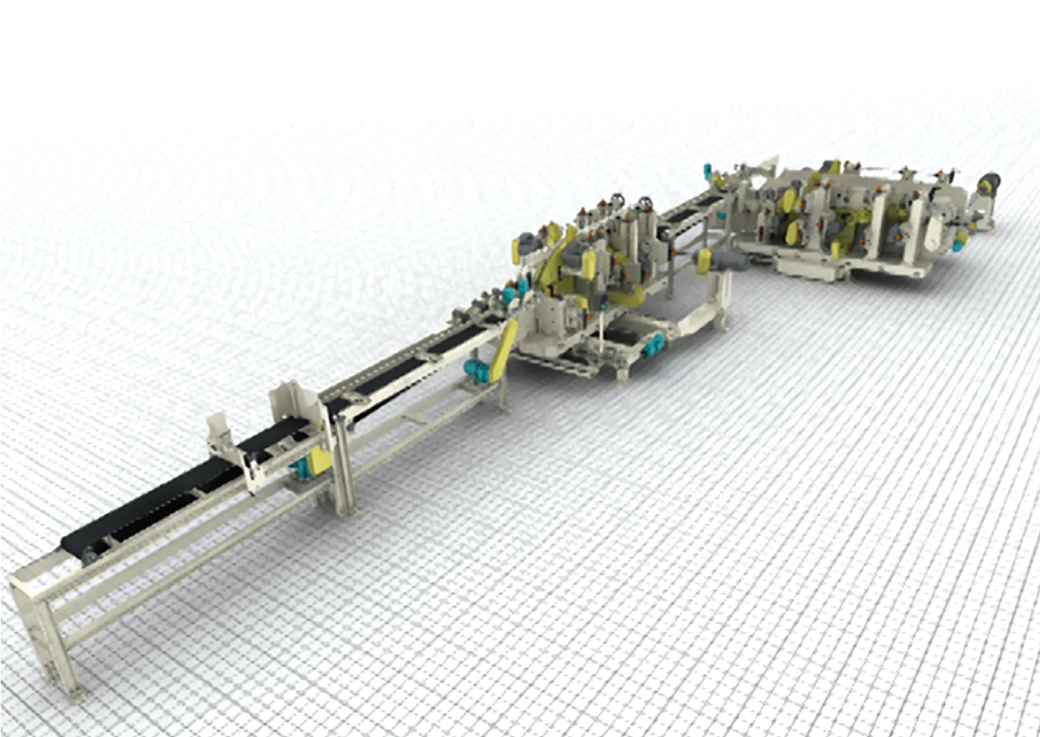

IST Series | Double End Tenoner

- Choice of Many of Models & Mechanisms

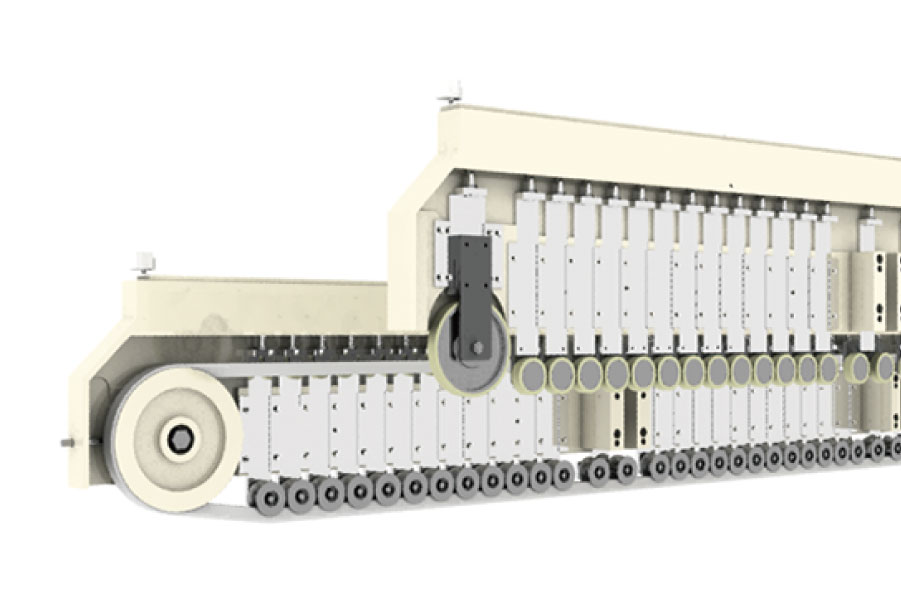

- Many Kinds of Various Caterpillar Chains

- Beveling and Slope Processing by Inclined Spindles

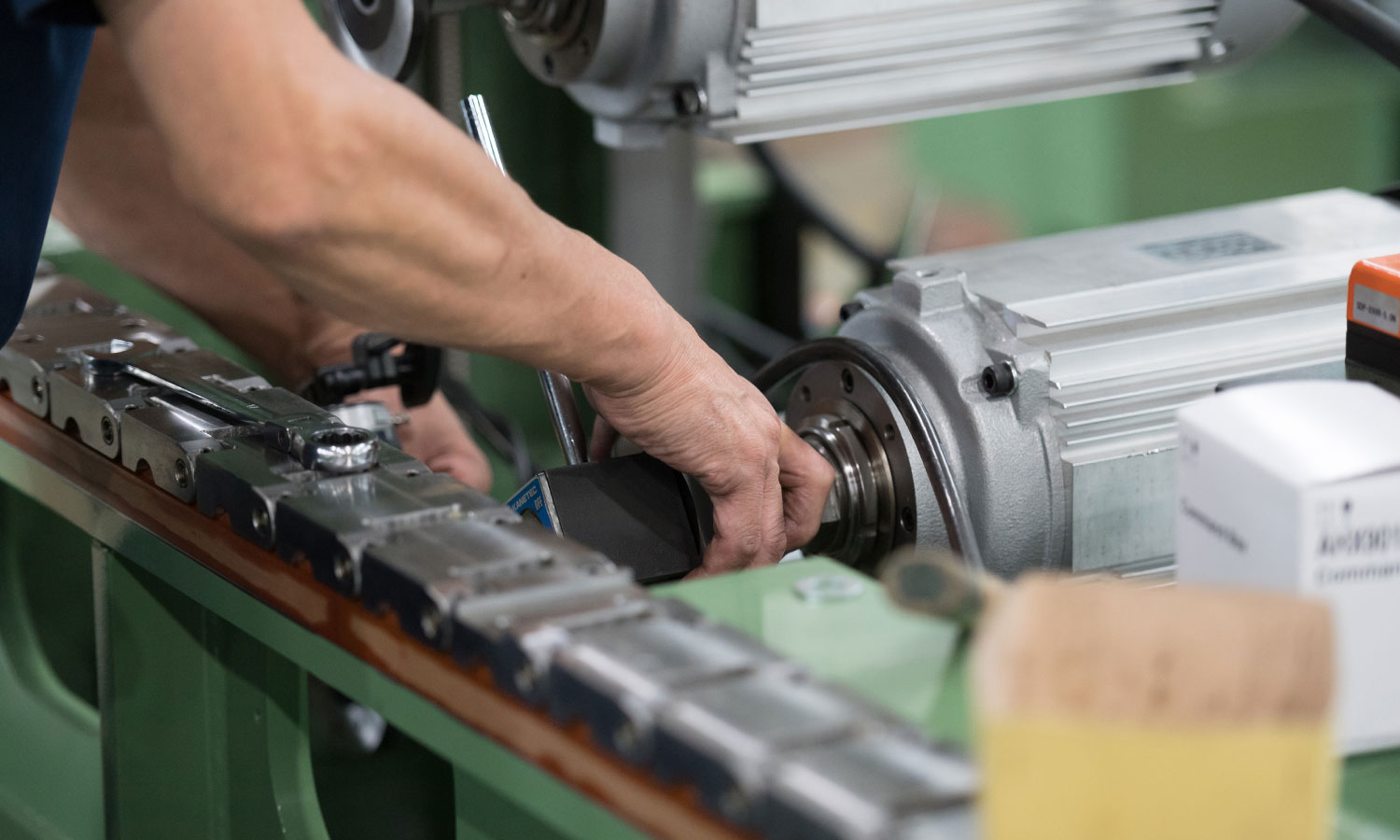

- Excellent Durability

- Body Cover (Optional)

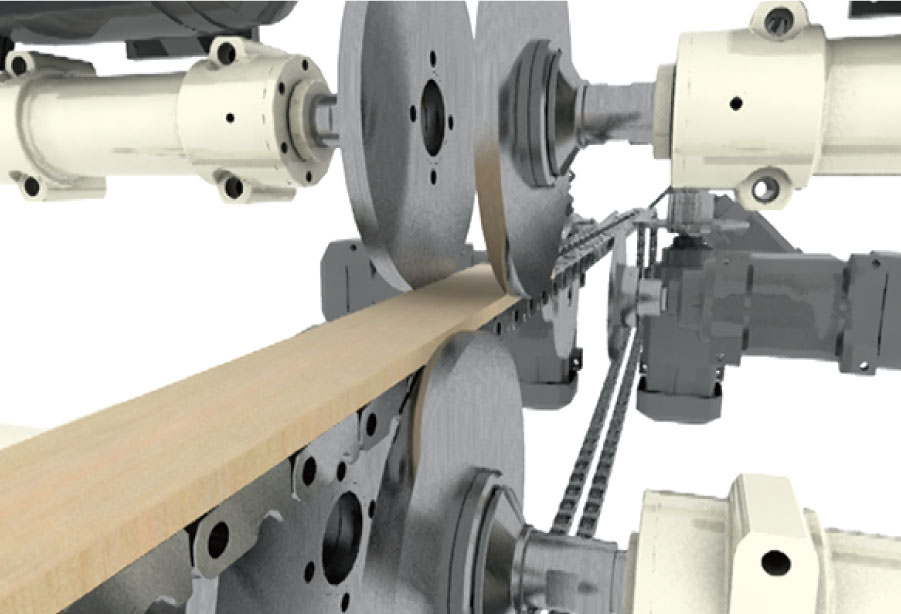

Various spindles specialized for hogging, molding and grooving. It’s possible to achieve high accuracy in cutting by positioning the materials & caterpillar chain closest to the cutting surface.

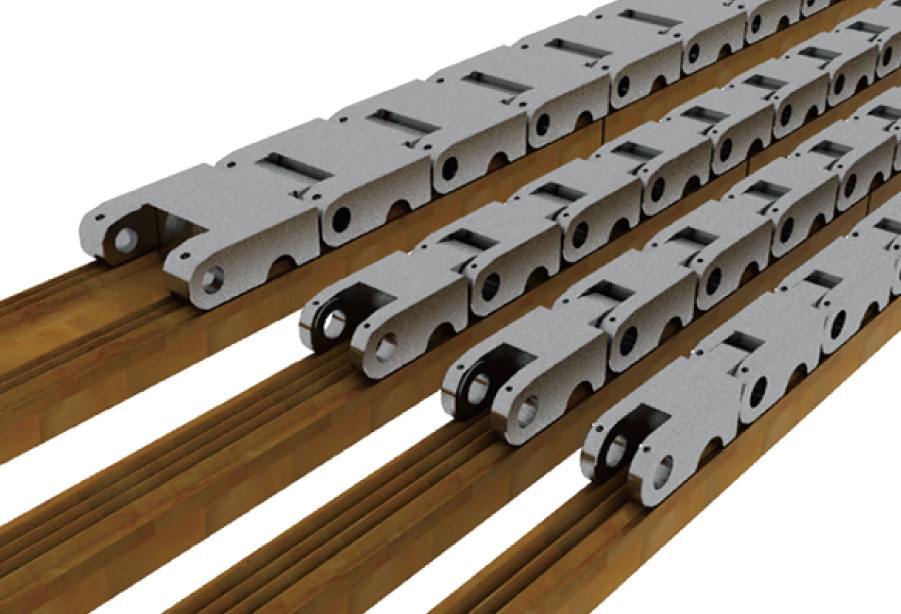

There are four different kinds of caterpillar chains, 75mm, 35mm, 30mm, 25mm. You can choose the width appropriate to materials’width. This is unique to our company not available from our competitors. It achieves to process with high accuracy.

* The 25mm-width caterpillar chains are specially customized parts (negotiable).

Air Cushion Style keeps the maximum pressing and pushing allowance without deviation. You can choose from roller or pressure belt which depends on materials. This is an example below.

Roller Type It’s often used by DET for length cutting.

Belt Type It’s often used by DET for cross cutting.

Direct drive spindles can change angles. In addition to beveling, it processes many different angles. You can change angles easily with an inclined scale.

You can choose a high frequency motor of direct drive type or belt drive type. As to a high frequency motor of direct drive type, you can easily change revolution speed by an inverter.(An inverter is an option)

The belt drive type’s speed is set by the pulley ratio.

As to cross cutting, it will be dog feeding on the long side basis.

Each material is fed with two dogs on both sides of the caterpillar chain, so that the machine enables to be right angle processing with high accuracy.